As cleaning technology continues to evolve, our methods of disease prevention become more effective. Electrostatic disinfectant has become a more widely used tool in preventing and responding to infectious disease exposure. This method has been proven to be extremely effective in accurate and thorough distribution of cleaning product into areas less reachable with traditional spray-and-wipe cleaning. When considering this addition to your cleaning protocol, it is important to have a solid understanding of what this treatment is, how useful it can be for your facility’s unique needs, and the best methods of implementation.

What is electrostatic cleaning?

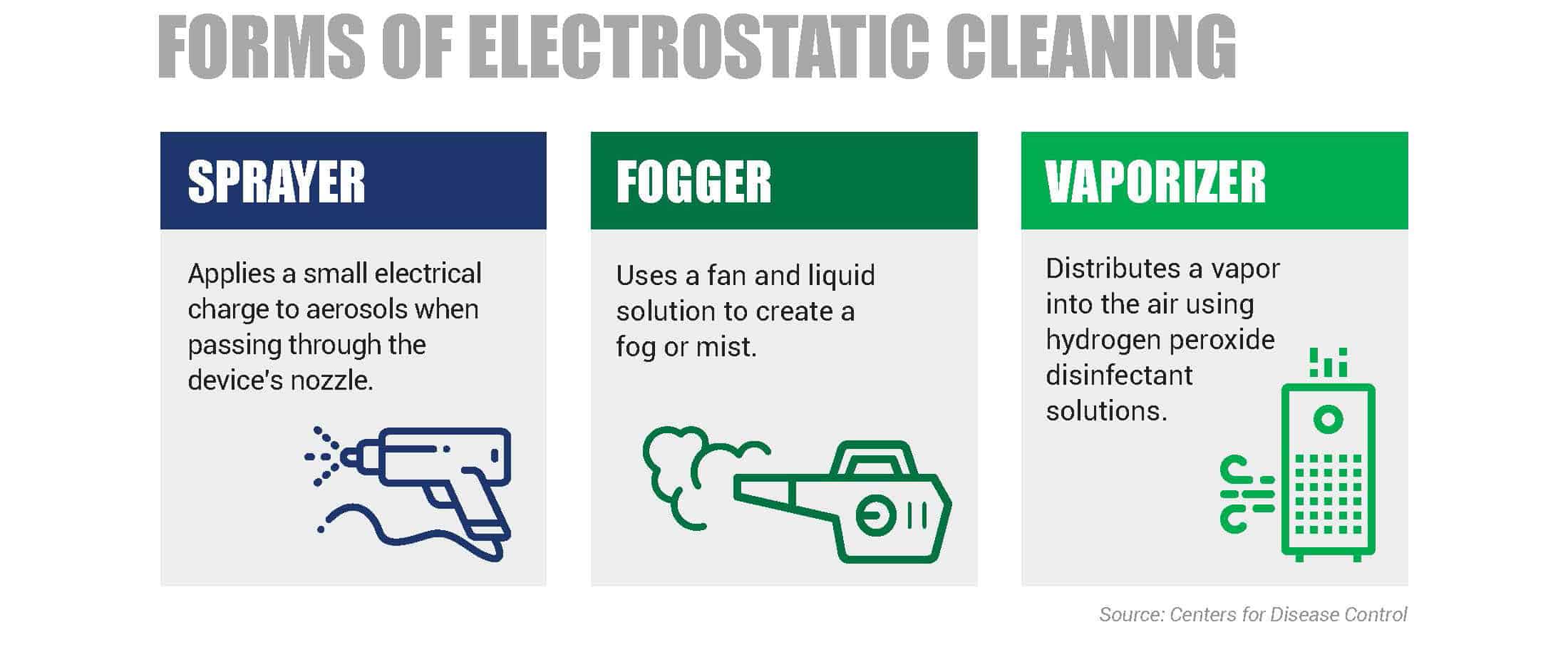

While electrostatic disinfection has become more popular since COVID-19, the technology itself has been around since the 1940s. A variety of disinfection methods are available, including sprayers, foggers, and vaporizers. All these tools have a simple idea behind them: the positively charged disinfectant attracts to the negatively charged surfaces, evenly coats them, and kills lingering germs. Disinfectants may need to be left undisturbed for a period (also known as “dwell time”) to maximize the efficiency of the product.

Choosing the type of tool you will use for electrostatic disinfection is important and can leave you with varying results. Restrooms, computer labs, and healthcare facilities are just a few examples of locations that require different approaches to the deployment of electrostatic cleaning. The types of electrostatic cleaning include:

· Foggers (also known as misters) create an aerosol substance and often are used alongside other cleaning protocols and methods.

· Sprayers electrically charge the cleaning product when it leaves the nozzle, causing disinfectant to attract toward the negatively charged surfaces nearby. Sprayers provide an even coating to the surface they clean.

· Vaporizers are generally used inside healthcare facilities or laboratories and require sealing up ventilation points in the space prior to use.

Preparation before usage

The key to successfully disinfecting your building with electrostatic methods is to be thorough in your preparation. PPE (Personal Protective Equipment) should always be utilized with electrostatic spraying or misting. The chemicals used in these products contain harmful substances that should not be breathed in or exposed directly to the human body. If using to disinfect against COVID-19, ensure your product is on the EPA’s List N of approved disinfectants for Coronavirus.

As part of your preparation, identify at-risk items within the confines of the space being treated, such as electronic devices or plants that should be covered. If sealed ventilation is required, such as when using a vaporizer, have the airways been double checked? If you are cleaning in a room that serves food, have you made sure to use approved products for food contact surface? Ensure surfaces are wiped down prior to using electrostatic processes as residue left on the surface to be treated may impact the effectiveness of the disinfectant. Consult package directions for proper “dwell time”, which is the amount of time the cleaning product should appear visibly damp on the treated surface, before resuming activity in the space to allow for maximum efficacy. Finally, ensure all employees conducting the disinfection or interacting with the area wash their hands promptly and thoroughly.

While electrostatic disinfection can serve as a powerful tool in the battle against infectious disease, it does require forethought and preparation prior to usage. When considering the implementation of this tool into your cleaning protocol, factoring in time and effort to prepare appropriately will make all the difference in maintaining facility integrity. Following the directions as labeled and understanding how products work will keep you, your facility, and your employees safe from harm while being able to effectively clean for health.